The transportation and installation of flexible welding

The transportation and installation of flexible welding tools is a meticulous and important process, and the following is a detailed summary and supplement to the information you have provided:

1. Handling method

Packing method:

1. The platform and accessories should be packed in wooden cases, and the interior should be protected by packaging film to prevent moisture or damage during transportation.

2. The center of gravity should be clearly marked on the outside of the wooden box so that it can be accurately judged and handled smoothly.

Handling precautions:

1. In the handling process, ensure that the wooden box is flat and flat, avoid excessive tilt, and the tilt Angle shall not exceed 30°.

2. When handling, be careful to avoid collision with standard accessories and ensure that all components are intact.

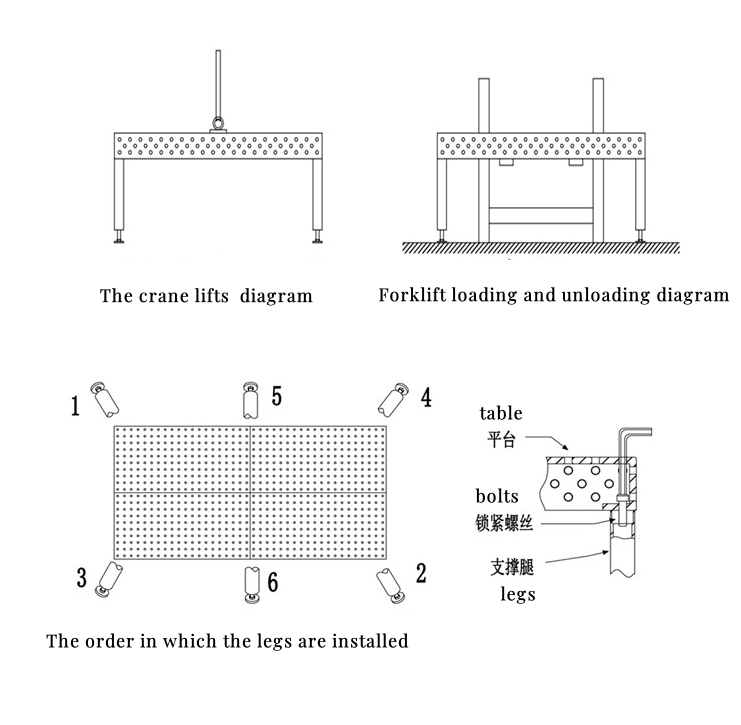

Installation method

Platform placement:

- After the platform is transported to the construction site, first open the wooden box to ensure that the platform faces up and is placed smoothly on the tie.

Support leg installation:

1. Prepare for fitting adjusting foot pads and support legs.

2. When installing the support legs, ensure that three of them are slightly longer for the main height adjustment position, and the other legs are slightly shorter for the fine-tuning support position.

3. Ensure that the platform is level and stable by adjusting the height of the foot pads and supporting legs.

Tools required:

1. Prepare all required tools, including at least one Allen wrench SW14, SW19, and 36 bayonet wrench or adjustable wrench.

2. These tools will be used in the installation process such as adjustment and fixing of the support legs.

Ground levelness considerations:

- When the horizontal inclination of the ground is greater than 15 degrees, it is recommended to use the frame type universal wheel support to ensure the stability and safety of the platform.

Precautions

1. Safety first:

1. In the entire transportation and installation process, safety should always be put in the first place, and relevant safety regulations and operating procedures should be observed.

2. Double check:

1. During the handling and installation process, carefully check whether all parts of the platform are intact. If any parts are damaged, replace or repair them in time.

3. Horizontal calibration:

1. After the installation is complete, use tools such as a level to calibrate the platform to ensure stability and accuracy.

4. Regular maintenance:

1. In the process of use, the platform should be regularly maintained and maintained, including cleaning, lubrication, etc., to extend the service life of the platform and maintain its good working condition.

In summary, the transportation and installation of flexible welding tools need to be carefully operated, pay attention to safety, and follow the relevant regulations and operating procedures. Through the correct handling and installation methods, you can ensure the stability and accuracy of the platform, and provide strong support for the welding work.