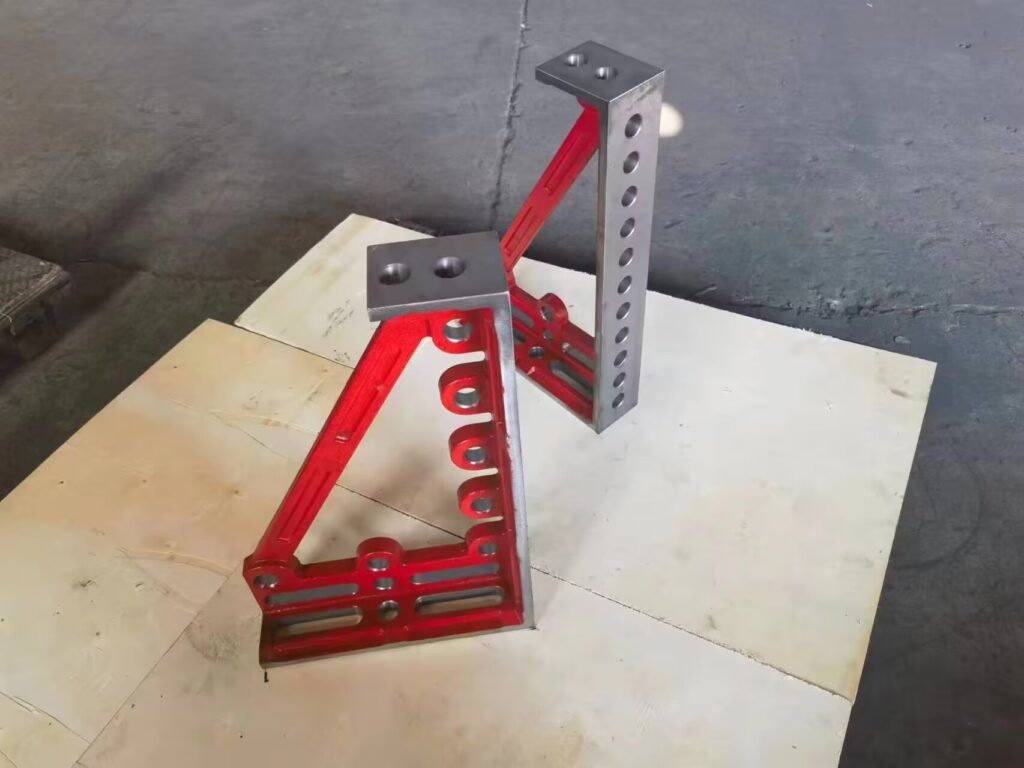

L-shaped square box – Casting

As a highly flexible and versatile tool, L-shaped multi-function square box has shown its unique advantages in many fields such as machinery manufacturing, equipment manufacturing and welding processing.

The following is a detailed analysis of its features, applications and product advantages:

Peculiarity:

- Four effective working faces: provide multiple working faces to meet the processing needs of different angles and directions.

- Accurate side hole distance: the side hole distance is designed to be 50±0.05mm to ensure high precision positioning and connection.

- Modular design: All four surfaces can be modular extension, expansion and combination to adapt to different sizes and shapes of the workpiece.

- Wide range of specifications: wide range of product specifications, up to 2000mm, to meet the production needs of different scales.

- Enhance the structure: When used vertically, it can increase the strength by supporting the Angle iron to ensure stability and durability.

- Focus on fire protection: fully consider the working environment when designing, pay attention to fire performance, and ensure the safety of use.

Apply

L-shaped square box as an accessory of 3D flexible welding platform, is widely used in the following fields:

Equipment manufacturing: used for positioning, clamping and machining of precision parts.

Welding processing: used as welding auxiliary tool in steel structure, vehicle body, rail transit, bicycle and motorcycle manufacturing, engineering machinery and other fields to improve welding accuracy and efficiency.

Sheet metal processing and metal furniture: used as support and positioning tools in the cutting, bending, welding and other processes of sheet metal.

Plant assembly and Industrial piping: Used to position and clamp parts such as flanges in plant assembly and industrial piping installation.

Test system: as an auxiliary tool of the test platform, to ensure the test precision and accuracy.

Product advantage

- Economy:

Low tooling cost: With the change of products, the tooling cost of L-shaped square box can be almost ignored, which reduces the production cost.

easy assembly: Users can freely splice according to demand, similar to assembling toys, convenient and fast. - Stability:

Durable: composed of cast iron, steel structural parts and high-precision workpiece, stable performance.

Parts replaceable: When parts are damaged, only a single part needs to be replaced, with low maintenance costs.

anti-splash treatment: Specially treated, inexpensive anti-splash solution can be used to protect the surface during welding. - Flexibility:

Multi-purpose: Flexible assembly and combination according to the shape and size of the workpiece.

Scale and module design: Scale and module dimensions are designed so that operators can quickly build L-shaped square boxes of the required size without measuring tools.

In summary, L-type multi-functional box with its economy, stability and flexibility, plays an important role in machinery manufacturing and related industries, and has become one of the indispensable tools in modern industrial production.

As a multi-functional, high-flexibility tool, L-shaped box has significant advantages in the fields of machinery manufacturing, equipment manufacturing and welding processing.

The following are the main advantages of L-shaped square boxes:

1)Versatility: The L-shaped square box has four effective working faces, and each face can be modular extension, expansion and combination, which makes it able to adapt to the needs of a variety of complex workpieces, whether it is positioning, clamping or processing, can provide stable and accurate support.

2)High precision: The design of L-shaped square box pays attention to accuracy, and the side hole distance is accurate to 50±0.05mm, ensuring the high precision of positioning. At the same time, its modular components and scale design make it easy for operators to build square boxes that meet workpiece dimensions without the need for complex measuring tools.

3)Economy and efficiency: The economy of L-shaped square boxes is reflected in many aspects. First of all, due to its modular design, users can freely combine according to actual needs, reducing the cost of new tooling that needs to be invested due to product changes. Second, when a component is damaged, only a single component needs to be replaced, and maintenance costs are low. In addition, the processing of the L-shaped square box allows the surface to be protected by using only inexpensive anti-splash liquid during the welding process, further reducing the use cost.

4)Stability and durability: The L-shaped square box is mainly made of high-quality materials such as cast iron and steel structural parts, and has extremely high stability and durability after precision processing. During long-term use, it can maintain stable performance and is not easy to deform or damage.

5)Flexibility: The design of the L-shaped square box fully considers the shape and size needs of different workpieces. According to the specific requirements of the workpiece, the user can quickly build an L-shaped square box that meets the requirements through a simple assembly combination. This flexibility allows L-shaped square boxes to adapt to a variety of complex production environments and improve production efficiency.

6)Easy to operate and maintain: The operation of the L-shaped square box is simple and easy to understand, even non-professionals can quickly get started. At the same time, its modular design makes maintenance more convenient. When parts need to be replaced or repaired, users can easily remove and replace damaged parts without complicated tools or skills.

7)Wide applicability: L-shaped square boxes have been widely used in equipment manufacturing, welding processing, sheet metal processing, metal furniture, equipment assembly, industrial pipelines and other fields. Its unique L-shaped structure and versatility make it one of the indispensable tools in these fields.

In summary, L-shaped square boxes play an important role in machinery manufacturing and related industries with their significant advantages of versatility, high precision, economic efficiency, stability and durability, flexibility and wide applicability.