3D welding table

Introduction

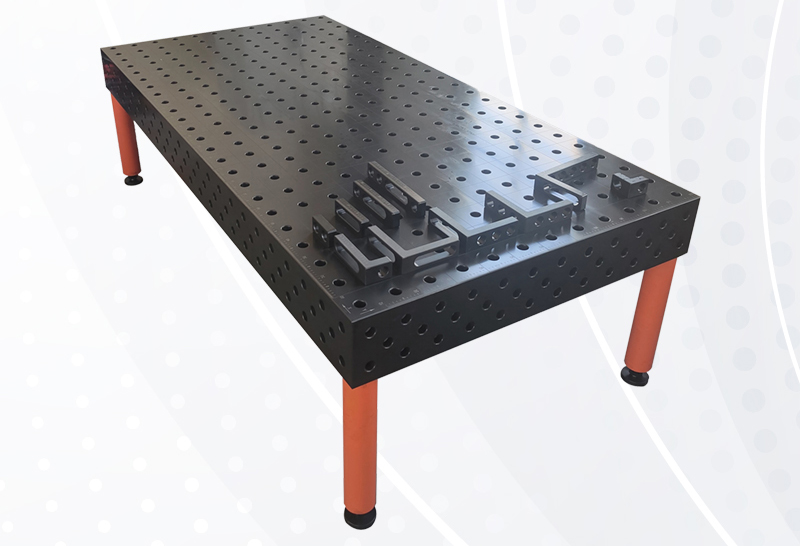

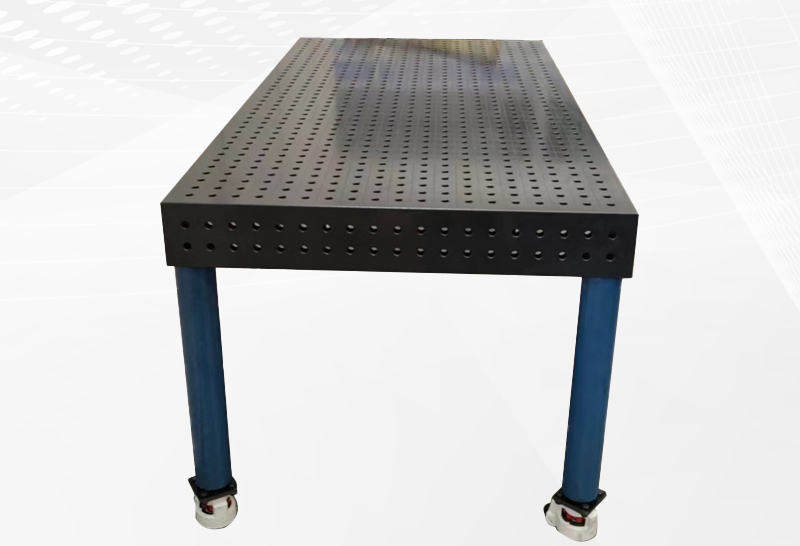

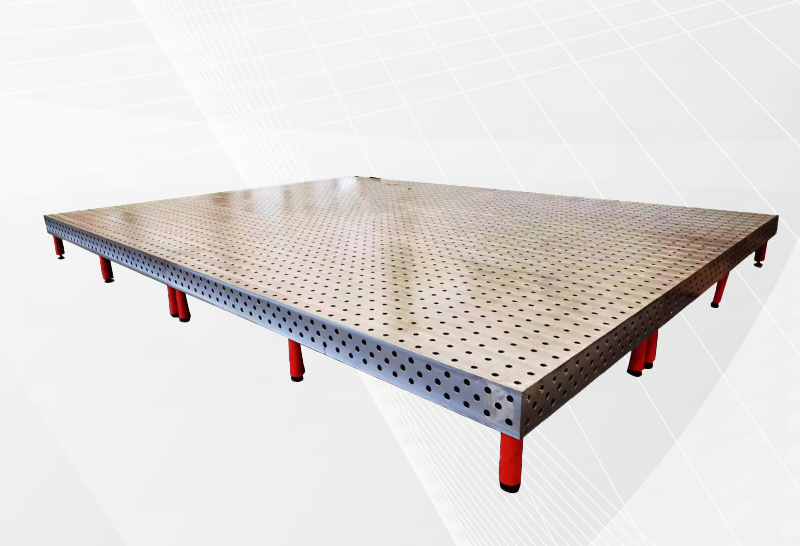

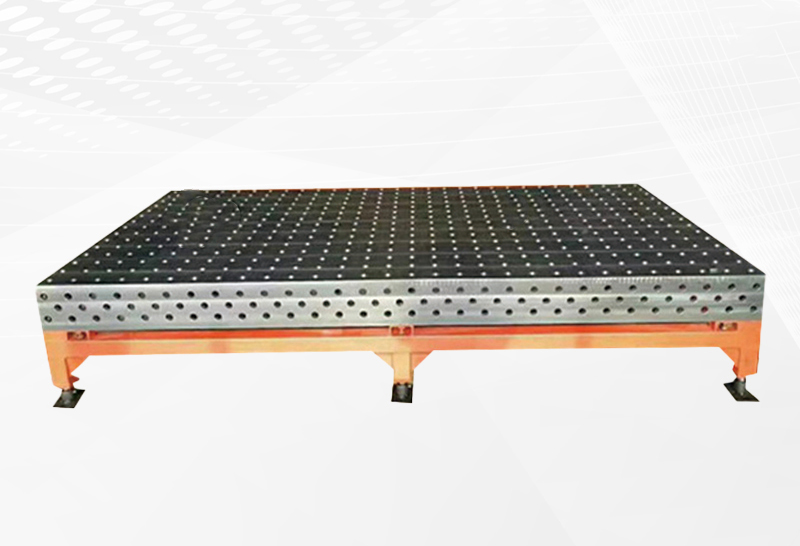

The 3D multifunctional welding platform is made of castings/steel parts, which is durable, stable and non-deformed, and flexible to adjust.

The precision 3D welding table is equipped with a clamp to set up your welding parts quickly and accurately. It meets all requirements for various applications.

The grid is engraved with corresponding grid lines.

According to customer requirements, the measuring scales can be drawn on the four sides of the platform.The Nitride finish protects the welding table against rust and weld spatter to make sure that the welding tables surface is kept extremely clean and accurate for fixturing.

3D Welding table -different Material

Steel Welding Table

Casting iron Welding Table

3D Welding table -different Hole diameter

D28 welding table

D16 welding table

| D28 3D welding table | |

| Sizes | Materials |

| 2000*4000*200 | Casting iron/steel |

| 2000*3000*200 | Casting iron/steel |

| 1500*3000*200 | Casting iron/steel |

| 1500*2500*200 | Casting iron/steel |

| 1500*2000*200 | Casting iron/steel |

| 2000*2000*200 | Casting iron/steel |

| 2000*2500*200 | Casting iron/steel |

| 1200*2400*200 | Casting iron/steel |

| 1200*1200*200 | Casting iron/steel |

| 1500*1500*200 | Casting iron/steel |

| 1000*1500*200 | Casting iron/steel |

| 1000*1200*200 | Casting iron/steel |

| 1000*1000*200 | Casting iron/steel |

| 800*1200*200 | Casting iron/steel |

| 1000*2000*200 | Casting iron/steel |

| 800*1000*200 | Casting iron/steel |

| D16 3D welding table | |

| Sizes | Materials |

| 1000*500*100 | Casting iron/steel |

| 1000*800*100 | Casting iron/steel |

| 1000*1000*100 | Casting iron/steel |

| 1200*800*100 | Casting iron/steel |

| 1200*1000*100 | Casting iron/steel |

| 1200*1200*100 | Casting iron/steel |

| 1500*600*100 | Casting iron/steel |

| 1500*1000*100 | Casting iron/steel |

| 1500*1200*100 | Casting iron/steel |

| 1500*1500*100 | Casting iron/steel |

| 2000*1000*100 | Casting iron/steel |

| 2000*1500*100 | Casting iron/steel |

| 2000*2000*100 | Casting iron/steel |

| 2400*1200*100 | Casting iron/steel |

| 3000*1000*100 | Casting iron/steel |

| 3000*1500*100 | Casting iron/steel |

| 3000*2000*100 | Casting iron/steel |

| 4000*2000*100 | Casting iron/steel |

Advantages of 3D welding table

- Modularity: All parts are classified, standardized, serialized, and matched with each other. By selecting fewer modules, a variety of positioning and clamping functions can be achieved.

- Flexibility: With a variety of assembly methods, users can achieve almost the same positioning and clamping functions as any fixture as long as they give full play to their imagination. Easy to assemble and disassemble; the workbench can be assembled at will according to the shape and size of the workpiece. The design of the scale and module size on the table allows the operator to set the required tooling according to the size of the workpiece without measuring tools.

- A D16 or D28 round hole is set every 50 or 100mm on the workbench and each functional module. The tolerance of any hole distance is less than 0.02mm, and this accuracy will be reflected in the products processed by the user, so some users also use this workbench as a reference platform for measuring tools.

- Design: Many functional modules are products, such as pin bolts for module connection and elastic clamps with compensation designed to prevent workpiece displacement during clamping.

Features of welding table clamps

GRID SPACING

- D28 system: 100±0.05mm

- D16 system: 50±0.05mm

- Diagonal has an extra hole in the center of each 4 hole grid, allowing for more possibilities.

PRECISION

- Table horizontal precision: 0.1/1000mm.

- Table vertical precision: 0.1/200mm.

- Drilling center accuracy: +/- 0.01mm.

LOADING CAPACITY

2 ton weight loading capacity.

WORKING SURFACE

All five working surfaces (1 top + 4 side surface) can be expandable via any of support tools.

MILLIMETER SCALE

Etched scale Marks allow the precise assembly of the element to be processed.

TABLE LEGS

- 4-10 support legs according to the size of the welding table.

- Optional steel frame and hydraulic lift box for choice.

SURFACE TREATMENT

Optional plasma nitriding coating.

Keep spatter from sticking better and Easy to remove welding slag.