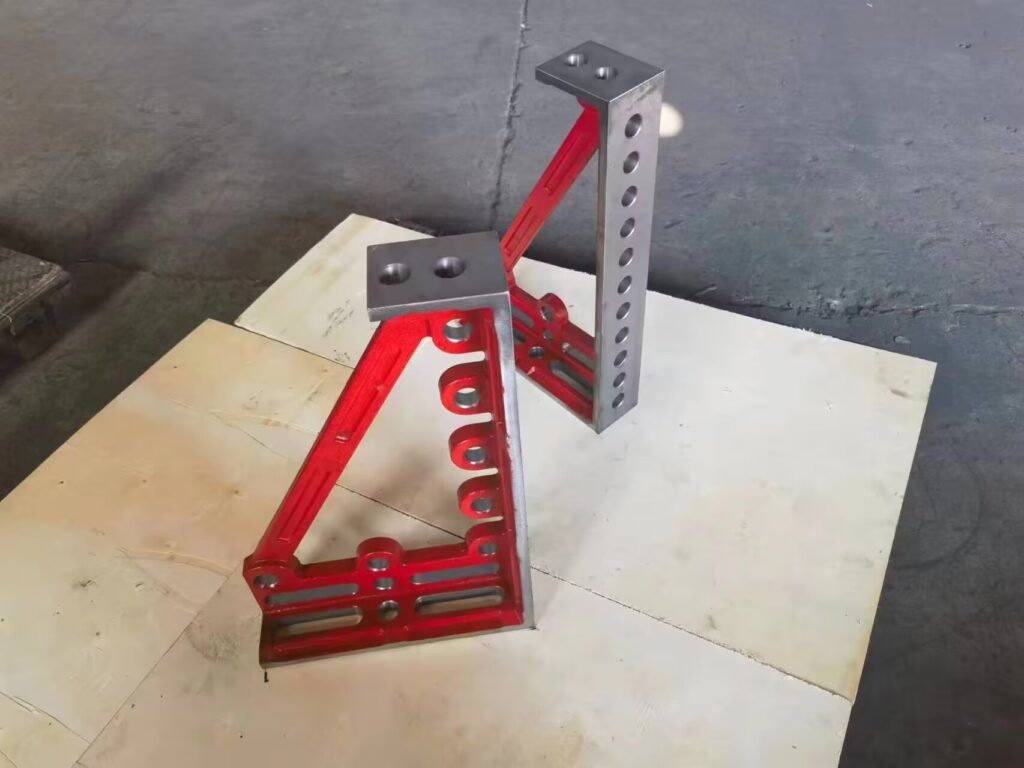

Supporting Angle iron

The supporting Angle iron in the 3D flexible welding platform accessories is an indispensable part of the platform, which plays a key role in the machining process.

The following is a detailed analysis of the Angle iron supporting the 3D flexible welding platform accessories:

1. Role and function

Height positioning: The supporting Angle iron can accurately position the support parts on the platform to ensure that the workpiece reaches the required height requirements during processing, thereby improving the processing accuracy.

Platform expansion: When the working area of the platform needs to be expanded, the supporting Angle iron can be used as a connector to combine multiple platforms to achieve flexible expansion of the platform.

Accessories positioning and compaction: the supporting Angle iron is also used to ensure that the workpiece is not displaced during processing, ensuring the stability and processing accuracy of the processing process. It is often used in conjunction with other fixtures to firmly press the workpiece.

Fixture table extension and clamping position provided: Support Angle iron can effectively extend the working area of the fixture table and provide additional clamping position for the workpiece to accommodate the machining needs of different sizes and shapes of the workpiece.

Arbitrary adjustment and precise positioning: The design of the support Angle allows flexible adjustment to meet the height and position requirements of different workpieces and machining needs. Through the precise adjustment mechanism, it is possible to ensure that the workpiece is accurately positioned at the desired position and height.

2.material and specifications

Material: The supporting Angle iron is generally made of castings, which can ensure that the supporting Angle iron has sufficient stability and durability during use.

Specifications: The specifications of the supporting Angle iron are various, including different lengths, widths, thicknesses, hole positions and connection methods. The common specifications are the D28 series and the D16 series, where the D28 series has a hole spacing of 100mm and the D16 series has a hole spacing of 50mm. Users can choose the appropriate specifications and models according to the actual processing needs and platform size.

3. purchase advice

Clear demand: In the purchase of supporting Angle iron, first of all to clear their own processing needs and platform size, in order to choose the appropriate specifications and models.

Focus on quality: quality is one of the key factors in the purchase of supporting Angle iron. Products produced by regular manufacturers should be selected and their materials, processes and accuracy should be checked to see if they meet the requirements.

Consider compatibility: the supporting Angle iron needs to be used in conjunction with other accessories of the three-dimensional flexible welding platform. The compatibility and compatibility with other accessories should be considered in the purchase to ensure the stability and reliability of the entire platform.

4. Summary

The supporting Angle iron of 3D flexible welding platform accessories plays an important role in the platform, which has the functions of height positioning, platform expansion and attachment positioning and pressing. In the purchase, users should consider their own needs, product quality and compatibility and other factors, choose the appropriate specifications and models. At the same time, with the continuous development of the manufacturing industry, the market prospect of three-dimensional flexible welding platform and its accessories is broad, worthy of attention and expectation.