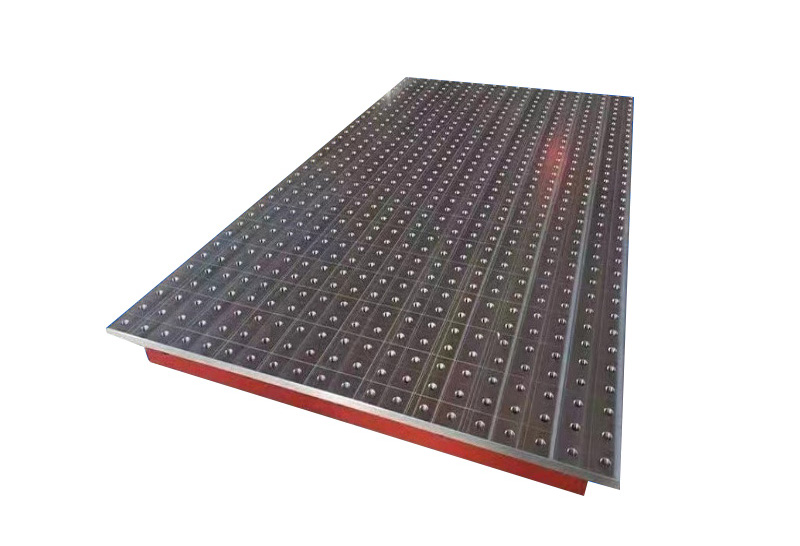

2D welding table

Introduction:

Precise 2D Welding Table is a typically flat and stationary welding table.

It provides a stable and level work surface for the welding process, ensuring accuracy and precision in joining metal pieces and is an essential tool for professional welders.

Key Features

Flat Surface: The primary feature is its perfectly flat surface, which ensures the workpieces remain level and aligned correctly during welding.

Grid Pattern: Many 2D welding tables have a grid pattern (usually in a 1-inch or 25-mm grid) marked or machined into the surface, aiding in measurement and alignment.

Holes and Slots: The tables often feature a series of holes or slots in the surface, which allow for the use of various clamps, fixtures, and accessories to hold the workpieces securely in place.

Material: Typically made from thick steel or cast iron to withstand the heat and sparks generated during welding.

Modularity: Some 2D welding tables are modular, allowing for extension or customization based on the size and shape of the workpieces.

2D Welding table -different Material

2D Steel welding table

2D Casting iron Welding Table

2D Welding table -different Hole diameter

D28 welding table

D16 welding table

| D28 3D welding table | |

| Sizes | Materials |

| 2000*4000*150 | Casting iron/steel |

| 2000*3000*150 | Casting iron/steel |

| 1500*3000*150 | Casting iron/steel |

| 1500*2500*150 | Casting iron/steel |

| 1500*2000*150 | Casting iron/steel |

| 2000*2000*150 | Casting iron/steel |

| 2000*2500*150 | Casting iron/steel |

| 1200*2400*150 | Casting iron/steel |

| 1200*1200*150 | Casting iron/steel |

| 1500*1500*150 | Casting iron/steel |

| 1000*1500*150 | Casting iron/steel |

| 1000*1200*150 | Casting iron/steel |

| 1000*1000*150 | Casting iron/steel |

| 800*1200*150 | Casting iron/steel |

| 1000*2000*150 | Casting iron/steel |

| 800*1000*150 | Casting iron/steel |

| D16 2D welding table | |

| Sizes | Materials |

| 1000*500*150 | Casting iron/steel |

| 1000*800*150 | Casting iron/steel |

| 1000*1000*150 | Casting iron/steel |

| 1200*800*150 | Casting iron/steel |

| 1200*1000*150 | Casting iron/steel |

| 1200*1200*150 | Casting iron/steel |

| 1500*600*150 | Casting iron/steel |

| 1500*1000*150 | Casting iron/steel |

| 1500*1200*150 | Casting iron/steel |

| 1500*1500*150 | Casting iron/steel |

| 2000*1000*150 | Casting iron/steel |

| 2000*1500*150 | Casting iron/steel |

| 2000*2000*150 | Casting iron/steel |

| 2400*1200*150 | Casting iron/steel |

| 3000*1000*150 | Casting iron/steel |

| 3000*1500*150 | Casting iron/steel |

| 3000*2000*150 | Casting iron/steel |

| 4000*2000*150 | Casting iron/steel |

Benefits:

Precision: Provides a reliable reference plane for precise welding, reducing errors and improving the quality of the welds.

Versatility: The grid pattern and holes allow for versatile positioning of clamps and fixtures, accommodating various shapes and sizes of metal workpieces.

Efficiency: Speeds up the setup process and helps maintain consistency across multiple welds.

Stability: The robust construction ensures a stable platform, reducing movement or warping of the table and the workpieces.

Safety: Securely holds workpieces, reducing the risk of movement during welding, which enhances safety.

HARDNESS

-Steel Welding Table: HV110-130

-Casting Welding Table: HB170-210

-Plasma Nitrating Steel Welding Table: HV550

HOLE DIAMETER

-D28 system: 28mm

-Drilled and milled hole.

GRID SPACING

– D28 system: 100±0.05mm

PRECISION

-Table horizontal precision: 0.1/1000mm.

-Drilling center accuracy: +/- 0.01mm.

LOADING CAPACITY

-2 ton weight loading capacity.

WORKING SURFACE

-One top working surface.

MILLIMETER SCALE

-Etched scale Marks allow the precise assembly of the element to be processed.

TABLE LEGS

– 4-6 support legs according to the size of the welding table.

– Optional steel frame and hydraulic lift box for choice.

SURFACE TREATMENT

– Optional Tempering Treatment

-Optional plasma nitriding coating.

WELDING SPATTER RESISTANT

-Keep spatter from sticking better and Easy to remove welding slag.