The difference between the 3D welding tables of cast iron and steel

There are significant differences between the cast iron three-dimensional welding platform and the steel three-dimensional welding platform in many aspects. The following is a detailed comparative analysis:

1. Material characteristics

Cast iron platform:

The material is generally HT250~300.

The interior of cast iron parts is composed of ferrite and a large amount of graphite. The relaxation characteristics of graphite make the residual stress of cast iron parts smaller. After aging treatment, the geometric accuracy can be maintained without deformation for a long time.

Cast iron has good vibration-absorbing properties, and its internal resistance is 3.2 times higher on average than carbon steel, which helps reduce vibration and noise.

Steel parts platform:

Carbon steel is usually used, and its elastic modulus and mechanical properties are better than cast iron.

Although the tensile strength of steel parts is lower than that of castings, its rigidity can also ensure the static geometric accuracy of the machine tool.

Large stress may be generated during the welding process, and internal stress relief needs to be carried out in a timely manner.

2. Processing and manufacturing

Cast iron platform:

The production cycle is relatively long and usually requires wooden mold making and smelting equipment.

The processing allowance is large, the aging time is long, and it takes up a large space.

The working surface of the cast iron platform can be processed into V-shaped, T-shaped, U-shaped grooves, dovetail grooves, round holes, long holes and other shapes to meet different needs.

Steel parts platform:

The production cycle is relatively short, the weight is light, and the machining allowance is small.

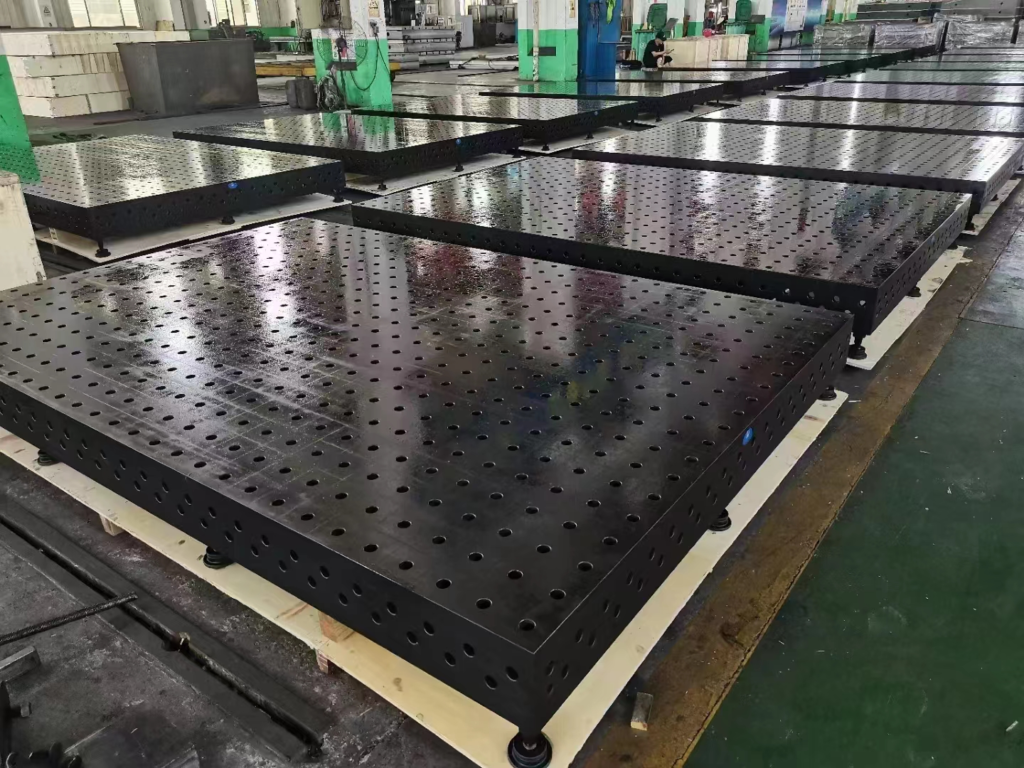

The five surfaces of the three-dimensional steel welding platform are all CNC machined. The working surface is evenly distributed with through holes and the hole spacing is fixed to facilitate quick positioning and clamping of the workpiece.

3. Application and performance

Cast iron platform:

The cast iron three-dimensional welding platform is suitable for occasions that require high accuracy and need to maintain accuracy for a long time.

Due to its good vibration absorption performance and stability, it is especially suitable for welding and assembly of large workpieces and heavy equipment.

Steel platform:

The three-dimensional steel welding platform has higher load-bearing capacity and rigid stability.

The flexible design allows the platform to be easily extended and expanded to accommodate workpieces of different sizes and shapes.

It has high accuracy and assembly precision. The center tolerance of the positioning hole of the work platform is within 0.05mm, which meets the needs of most welding and assembly processes.

4. Maintenance

Cast iron platform:

Cast iron platforms require regular maintenance and upkeep during use to maintain their accuracy and stability.

Steel platform:

Steel parts platforms also need to pay attention to maintenance and upkeep during use, especially the stress and deformation generated during the welding process need to be dealt with in a timely manner.

In summary, there are significant differences between the cast iron three-dimensional welding platform and the steel three-dimensional welding platform in terms of material characteristics, processing and manufacturing, application and performance, cost and maintenance. Which platform to choose depends on factors such as specific application scenarios, workpiece types, accuracy requirements, and cost budgets.