The supporting Angle iron

The supporting Angle iron in 3D flexible welding platform accessories is an indispensable part of the platform. Its main functions are:

Altitude fixing

Platform expansion

Attachment positioning and compaction

Fixture table extension with clamping position provided

Arbitrary adjustment and precise positioning

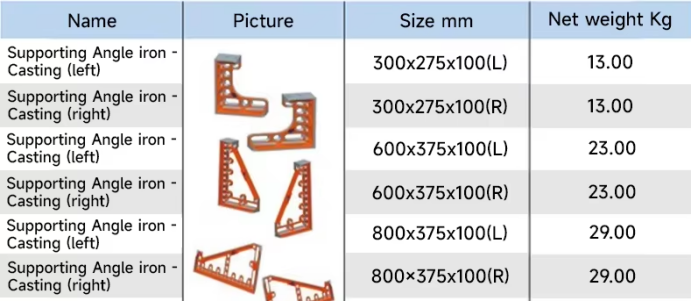

Material: The supporting Angle iron is generally made of castings, which can ensure that the supporting Angle iron has sufficient stability and durability during use.

The supporting Angle iron technical datas

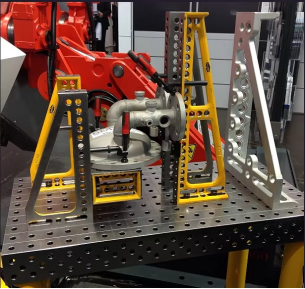

The supporting Angle iron Application

The following is a detailed description of the specific use of the supporting Angle iron

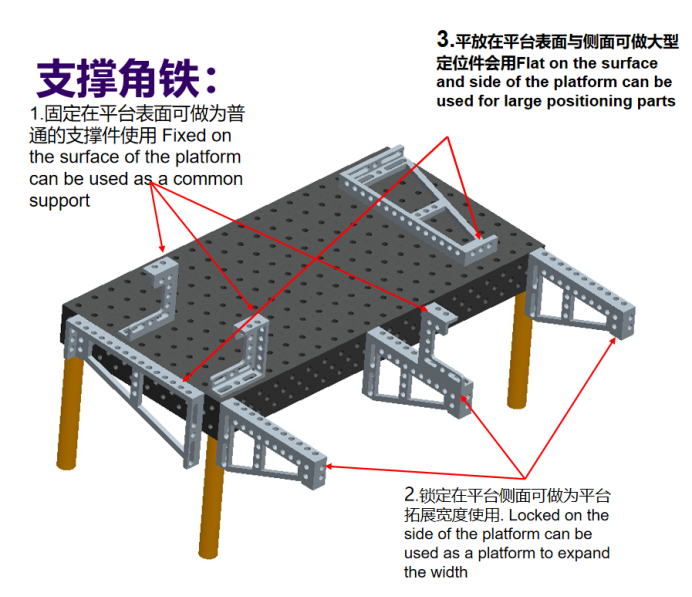

Height positioning: The supporting Angle iron can accurately position the support parts on the platform to ensure that the workpiece reaches the required height requirements during processing, thereby improving the processing accuracy.

Platform expansion: When the working area of the platform needs to be expanded, the supporting Angle iron can be used as a connector to combine multiple platforms to achieve flexible expansion of the platform.

Attachment positioning and compaction: the supporting Angle iron is also used to ensure that the workpiece is not displaced during processing, ensuring the stability and processing accuracy of the processing process. It is often used in conjunction with other fixtures to firmly press the workpiece.

Fixture table extension and clamping position provided: Support Angle iron can effectively extend the working area of the fixture table and provide additional clamping position for the workpiece to accommodate the machining needs of different sizes and shapes of the workpiece.

Arbitrary adjustment and precise positioning: The design of the support Angle allows flexible adjustment to meet the height and position requirements of different workpieces and machining needs. Through the precise adjustment mechanism, it is possible to ensure that the workpiece is accurately positioned at the desired position and height.