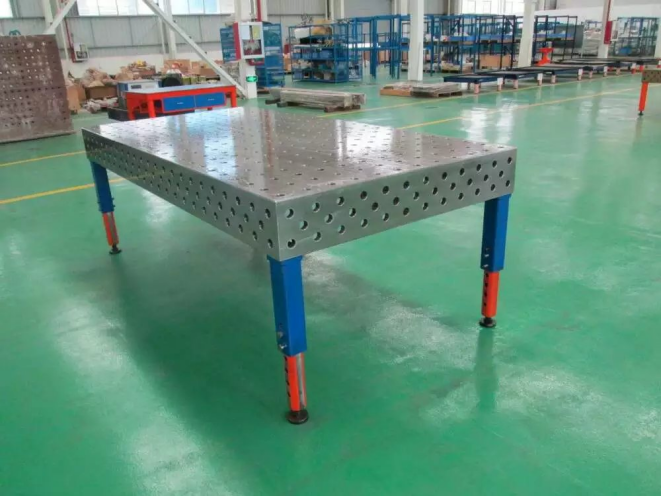

3D welding table

Three-dimensional welding platform, also known as 3D flexible welding Tables, is a new type of work equipment widely used in the field of welding.

It is a working surface designed for welding process, based on the five working surfaces of the standard hole grid and the working surface of the front grid line, equipped with various accessories for positioning, clamping and supporting. These accessories are quickly connected by means of pins and bolts for fast positioning and clamping of workpieces. Suitable for a wide range of welding and assembly processes.

Welding table technical data

| 3D welding table — D28 series | ||||||||

| Aperture | Hole spacing | Flatness | Verticality | Surface roughness | Standard load bearing | Frame bearing | Nitriding hardness | Specifications |

| φ28.065–φ28.149mm | 100±0.05mm | 0.1/1000mm | 0.1/200mm | RA3.2 | 2T | 5T | HV450~HV630 | 1000*1000~2000*4000mm |

| 3D welding table — D16 series | ||||||||

| Aperture | Hole spacing | Flatness | Verticality | Surface roughness | Standard load bearing | Frame bearing | Nitriding hardness | Specifications |

| φ16.065–φ16.149mm | 50±0.05mm | 0.1/1000mm | 0.1/200mm | RA1.6 | 2T | 5T | HV450~HV630 | 1000*1000~2000*4000mm |

3D Welding table production working flow

Casting/Welding – Machining – Finishing – nitriding – packaging

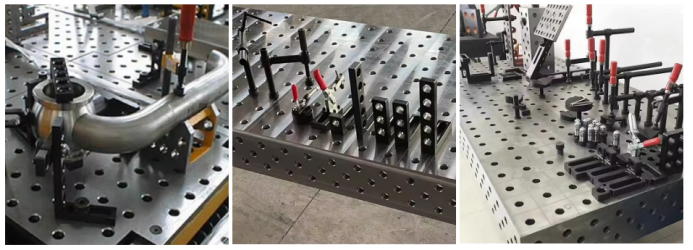

1. Tools for supporting: U-Shaped cube case, L-shaped cube case, Angle supporting, and Angle gauge.

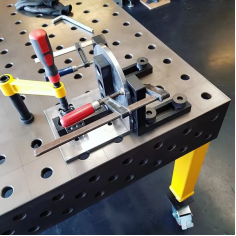

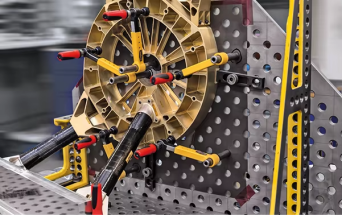

2. Spare parts for Locating: positioning square, positioning ruler, flat square, V-shaped positioning piece.3. Tools for clamping:fixed quick clamping piece (screw clamping), retractable clamping piece (screw clamping), 45 degree clamping piece (screw clamping), etc.

4. Tools for fixing: quick locking pin, countersunk locking pin, countersunk quick locking pin.

5. Other matching tools and accessories: height adjuster, lifting ring, tool cart, grounding device, adjusting gasket, hexagon wrench, nylon brush, oil stone, oil can,etc.

3D welding table Widely used in the manufacturing and processing of mechanical processing equipment, engineering machinery, railways, tracks,automobiles, ships, construction industries, sheet metal processing, testing and measuring instruments, and steel structures.

Modular and more cost-effective

All components are classified, standardized and serialized, and matched with each other. With the least number of modules, a variety of fast positioning and clamping functions can be achieved.

Flexible, more versatile

Fast assembly, convenient disassembly and assembly, stronger repeatability. Users can also add a small number of positioning components according to their own needs, which can meet specific requirements.

High precision, more accurate production

Working table and various functional modules have high processing accuracy, for large work pieces about 3m square, after using a reasonable program to weld, its flatness, straightness, parallelism and perpendicularity can be controlled within ±0.1mm.

Corrosion resistance, long service life

Integrated casting greatly increases the overall structure. The platform has undergone heat treatment, and the salt spray test has reached level ten or above.